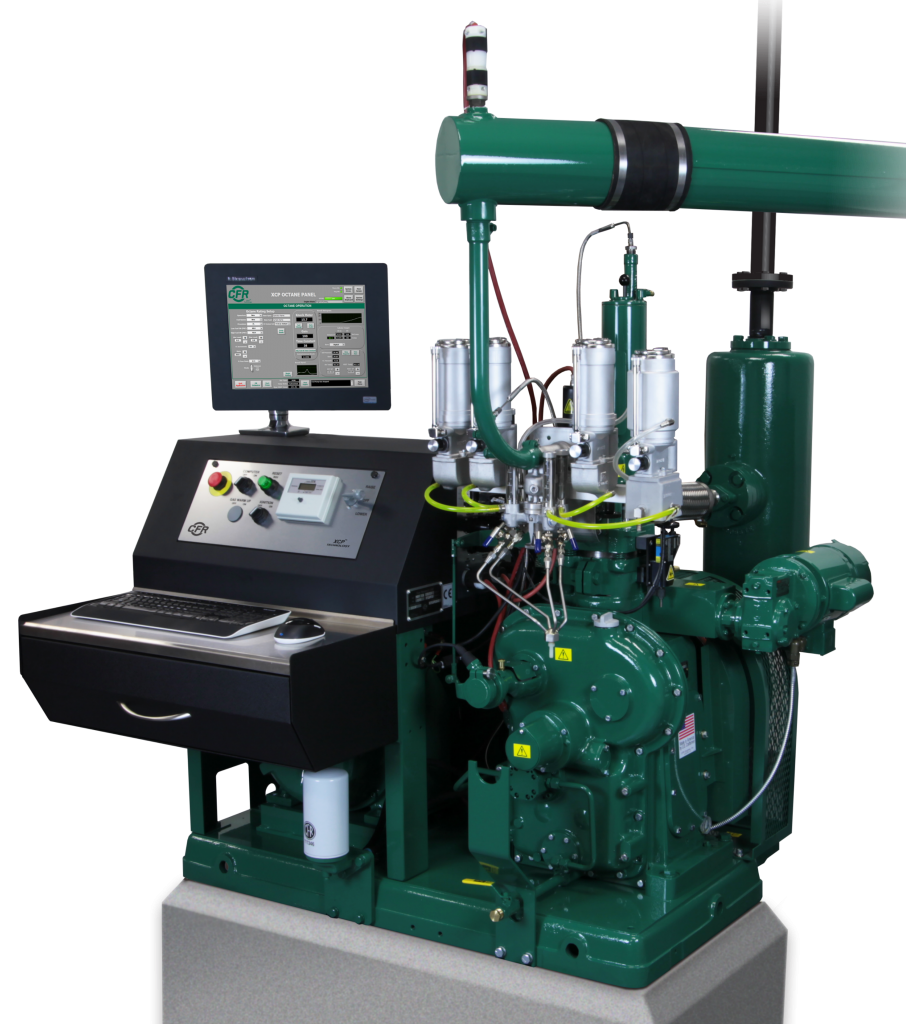

CFR Engines Inc. Octane Rating Unit

Combination Research & Motor Method

Model: F1/F2

The CFR® F1/F2 Octane Rating Unit is the globally accepted standard for determining and certifying the anti-knock characteristics of motor fuels – whether gasoline, fuel constituents, or alternative fuels. Since the release of the first CFR octane rating engines in 1929, CFR has been at the forefront of establishing test methods for rating fuels. Working hand-in-hand with the automotive and petroleum industries, we continue to enhance the CFR product line to help fuel producers and engine manufacturers develop products that perform together more effectively.

The CFR F1/F2 octane rating engines are specified equipment for testing fuels according to:

ASTM D2699: Standard Test Method for Research Octane Number of Spark-Ignition Engine Fuel

ASTM D2700: Standard Test Method for Motor Octane Number of Spark-Ignition Engine Fuel

IP 236: Determination of Knock Characteristics of Motor and Aviation Fuels – Motor Method

IP 237: Determination of Knock Characteristics of Motor Fuel – Research Method

Click here for F1/F2 Brochure

Confidence in a Fully integrated Fuel Testing System

A complete CFR Engines Inc. octane fuel testing system includes four main elements, each designed to seamlessly integrate and deliver trusted results. With the Engine Air Control System, the F1/F2 octane rating engine, XCP™ Technology, and a CFR® exhaust surge tank; each critical parameter of a successful octane test is controlled. Whether working with a complete unit, an upgrade/conversion kit, or a genuine CFR service part; the product has been designed, manufactured, and fully tested by CFR to work as an integrated solution for your operation. Confidence in the CFR octane rating system to do its job, allows users to focus less on making the system work and focus more on what else they need to do.

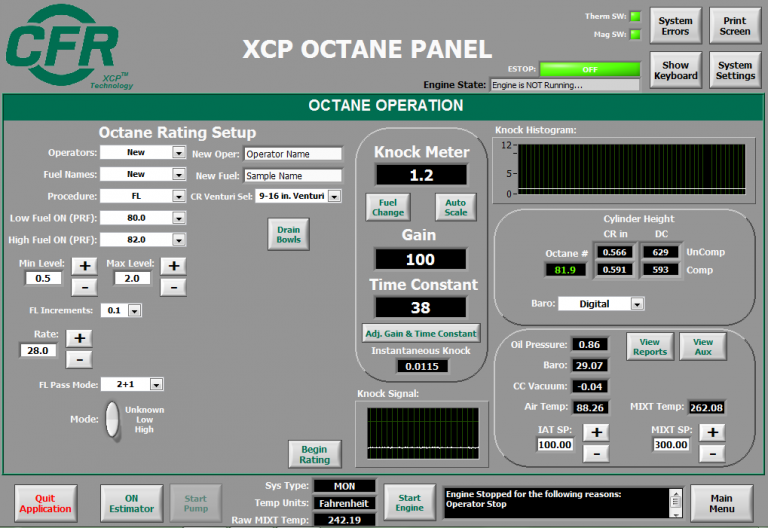

Data Integrity with XCP Technology

With the XCP Digital Control Panel, critical information for each rating is automatically captured and presented in a ready-to-use Excel-based report, minimizing manual data recording and calculating errors. The standard report of XCP includes KI values, Octane Numbers, environmental data (temperatures, pressures, barometer, and EACS humidity), and KI vs fuel level curves. The XCP is also capable of being integrated into a Laboratory Information Management System (LIMS). Automatic capture and processing of test data gives the accountability needed to defend ratings without challenge.

Reliability of Proven Design

Since 1929, thousands of users have relied on the proven service of CFR Engines Inc. products. This reliability has been consistently maintained through a long series of well-designed system upgrades and product enhancements. CFR octane and cetane testing systems and components, such as the robust engine crankcase and cylinder/head, are built to deliver unsurpassed operating life. With basic maintenance and upkeep, a user can expect CFR octane rating engines to consistently withstand the demands of today’s fuel testing environment with a true engine-based Octane Number.

Precision through Modern Instrument Control

The CFR F1/F2 Octane Rating Unit with XCP Technology uses digital instrumentation to record and process critical aspects of system operation and performance. On-board barometric pressure adjustments, increased automation, broad octane meter range, no adjustments for “spread”, and even control of engine intake air are some of the many advantages of the CFR fully integrated instrument system. More accurate measurements controlled by and intuitive interface lead to better overall precision.

Cost Savings with One System Flexibility

With standard product offerings, a CFR F1/F2 Octane Rating System provides the user unmatched flexibility and cost savings. With a few simple component changes and push button control, users can easily switch between any of the four test procedures in ASTM Methods D2699 or D2700. Cost savings are realized in greater utilization of resources, quicker test changes, reduced operator training, and improved repeatability with a single system.

Other Important Features

- XCP integrated safety monitoring system and shutdown protections for: power loss, low oil pressure, overheating, and electrical overload

- Easy-to-use touch-screen HMI panel for unit operation and octane rating tests

- Built-in prompts guide the operator through the test procedures for all of the ASTM methods; improving consistency between operators

- Simple design of the thermal siphon, ebullient, recirculating type cooling condenser maintains constant cylinder jacket water temperature for stable operation

- XCP Technology intuitive and user-friendly, and operators require less training to achieve proficiency in octane and cetane testing

- Digital knock meter displays actual knock intensity value, eliminating the need for visual interpretation of an analog meter by the operator

- Electronic maintenance log of vital maintenance information that is documented for future reference

- Non-contact laser sensor accurately measures cylinder height and displays results on-screen, providing more accurate test results

- Synchronous/reluctance motor provides power for starting and absorbs engine output to maintain constant speed

- Electronic on-board barometer automatically corrects cylinder height for barometric pressure

- Environmentally friendly resistance temperature devices (RTDs) for management of critical temperature variables

- Built-in diagnostic feature provides a way to troubleshoot the octane rating unit when maintenance is needed

- On-screen operations and maintenance manuals for easy access