Frontier Technology Issues: Lithium-ion batteries: a pillar for a fossil fuel-free economy?

Download Frontier Technology Issues: Lithium-ion batteries: a pillar for a fossil fuel-free economy? (PDF)

Download Frontier Technology Issues: Lithium-ion batteries: a pillar for a fossil fuel-free economy? (PDF)

Introduction

In 2019, the Royal Swedish Academy of Sciences awarded the Nobel Prize in Chemistry to three scientists for the development of lithium-ion (Li-ion) batteries that, according to the Academy, have laid the foundation for a fossil fuel-free economy. Li-ion batteries can safely store large amounts of energy, ensuring stable and predictable flows of electricity even in decentralized immobile (i.e., stationary) or mobile modes in remote areas. The increasing popularity of passenger electric vehicles and electric buses is largely a result of the capacity improvement of Li-ion batteries and significant price declines due to investment in productive capacity.

It is the urgent and inescapable mandate for the entire humanity to reduce greenhouse gas (GHG) emissions to mitigate climate change and build a fossil fuel-free economy. As examined below, the utility and transport sectors have been the two major emitters of GHGs and, without reducing GHGs from these two sectors, the Paris Agreement of limiting global warming to 1.5 C cannot be achieved. Li-ion batteries have been a promising clean technology because the battery stores energy in its cells, as opposed to generating energy by combusting fossil fuels in a gasoline and diesel engine, to power a vehicle or provide electricity to a building (see box 1 for the capability of Li-ion batteries). When batteries are recharged with fossil fuel-free electricity, Li-ion batteries fully contribute to a fossil fuel-free economy.

This Frontier Technology Issues examines the recent trends in production and use of Li-ion batteries, in which the two major emitters, utility and transport sectors, have been the two largest users of Li-ion batteries. It considers how the applications of the batteries in the two sectors are expected to reduce GHG emissions. The last section examines the role of governments in removing technological and economic obstacles and encouraging the wider application of Li-ion batteries.

Lithium-ion batteries are helping reduce greenhouse gas emissions

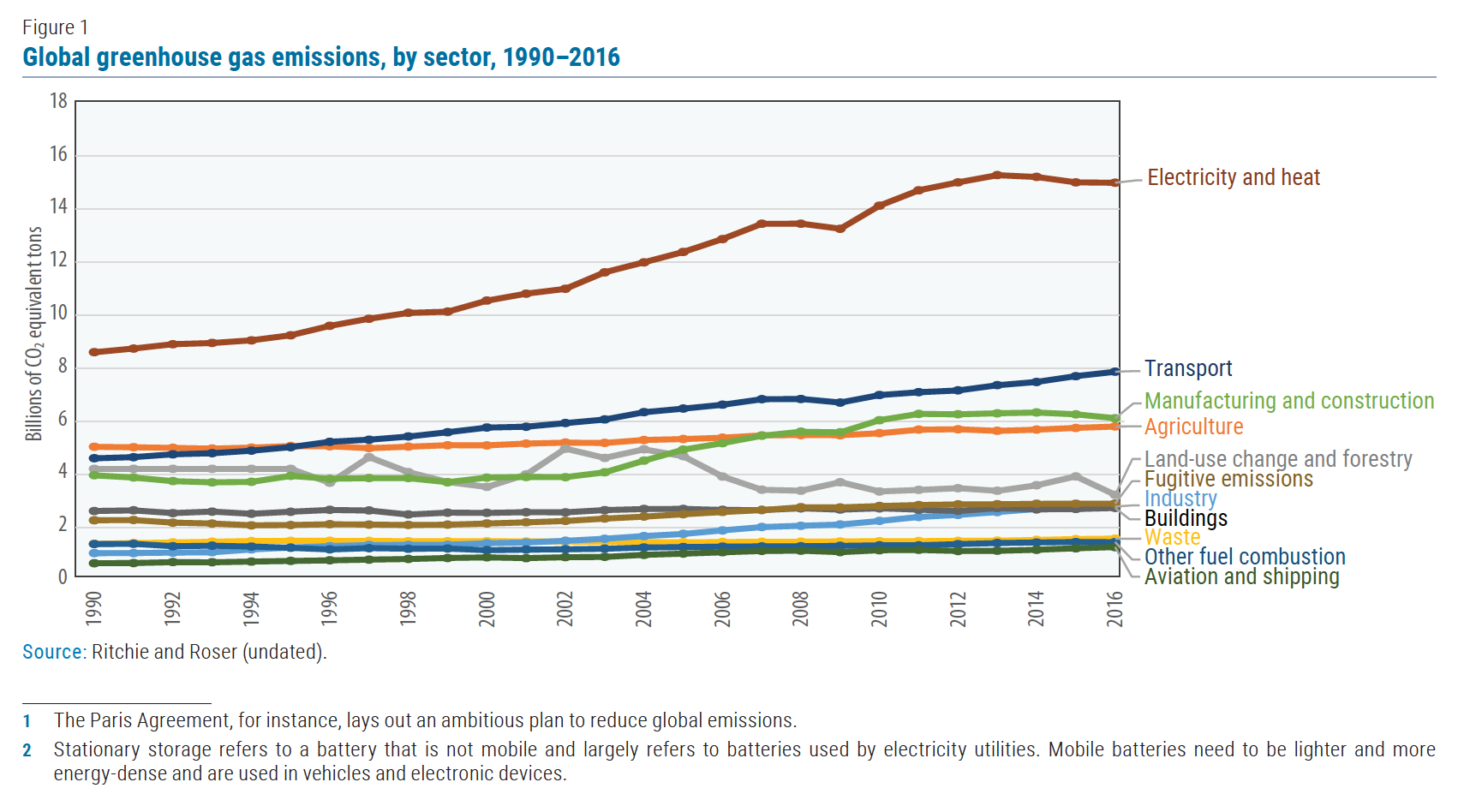

To mitigate climate change and create a fossil fuel-free economy, the global community has agreed that GHG emissions must be reduced rapidly and significantly.1 Human activities have emitted about 50 billion tons of GHGs (CO2 equivalent) at the global level every year from the mid-2010s, in which the electricity and heat sector is the dominant emitter, followed by transport, manufacturing and agricultural sectors (figure 1).

Li-ion batteries are a promising clean technology to replace the conventional fossil-fuel powered device. Batteries have been particularly important in the two sectors most responsible for GHG emissions: electricity generation and transport. Even more importantly, the gains of one sector are leading to further gains in the other, creating a virtuous cycle of lower cost, greater production, and greater demand.

In electricity generation, inexpensive Li-ion batteries are enabling grids to install more renewable energy capacity using solar and wind sources.2 One of the well-known shortcomings of solar and wind-power energy sources is their large variability in power generation. The sun does not always shine, and the wind does not always blow. Batteries are used to store up surplus power when generation is abundant for use or to distribute power when there is a deficit. In addition, the large capacity of batteries to store energy can reduce the maximum capacity needed by power plants (and associated construction costs), which are designed to meet the estimated peak demand during, say, a hot summer day when the use of air conditioners are above normal.

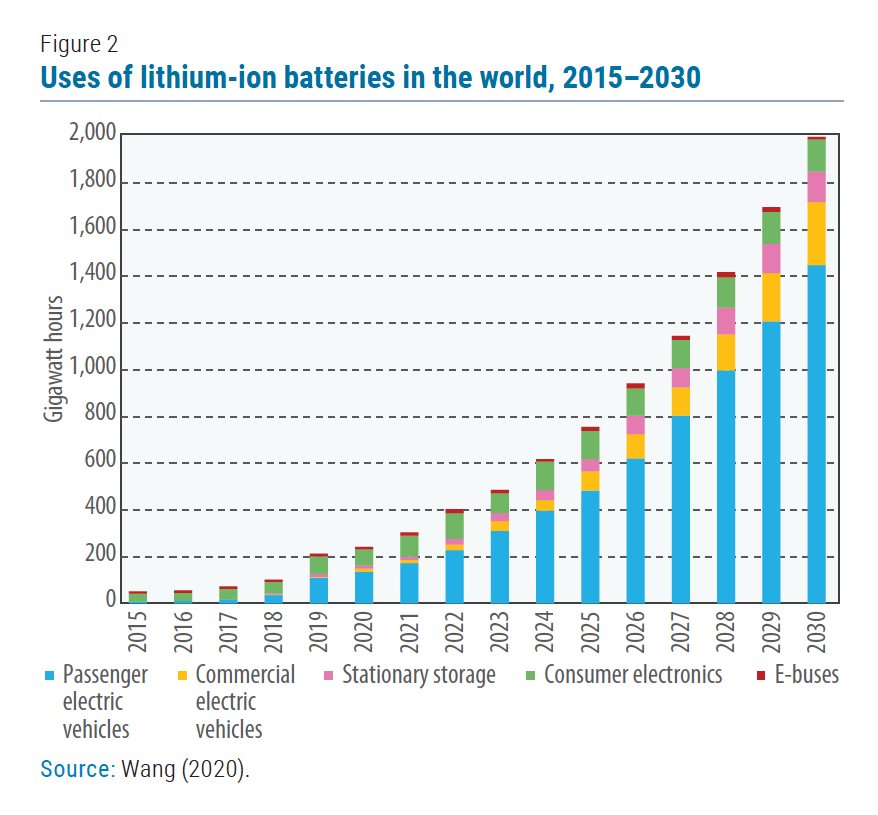

In the transport sector, batteries are enabling a revolution in electric vehicles of all types. Li-ion batteries can help manufacturers replace conventional automobiles with combustion engines powered by fossil fuels. In the United States market alone, global manufacturers have announced plans to introduce nearly 100 purely electric vehicle models by the end of 2024 (Preston, 2021). Demand for Li-ion batteries has grown from mere 19 gigawatt hours (GWh) in 2010 to 285 GWh in 2019. It is forecast to reach 2,000 GWh in 2030—about 8 per cent of world energy supply (figure 2). Passenger and commercial electric vehicles continue to be the dominant uses of Li-ion batteries in terms of capacities installed, followed by stationary (energy) storage.

In the transport sector, batteries are enabling a revolution in electric vehicles of all types. Li-ion batteries can help manufacturers replace conventional automobiles with combustion engines powered by fossil fuels. In the United States market alone, global manufacturers have announced plans to introduce nearly 100 purely electric vehicle models by the end of 2024 (Preston, 2021). Demand for Li-ion batteries has grown from mere 19 gigawatt hours (GWh) in 2010 to 285 GWh in 2019. It is forecast to reach 2,000 GWh in 2030—about 8 per cent of world energy supply (figure 2). Passenger and commercial electric vehicles continue to be the dominant uses of Li-ion batteries in terms of capacities installed, followed by stationary (energy) storage.

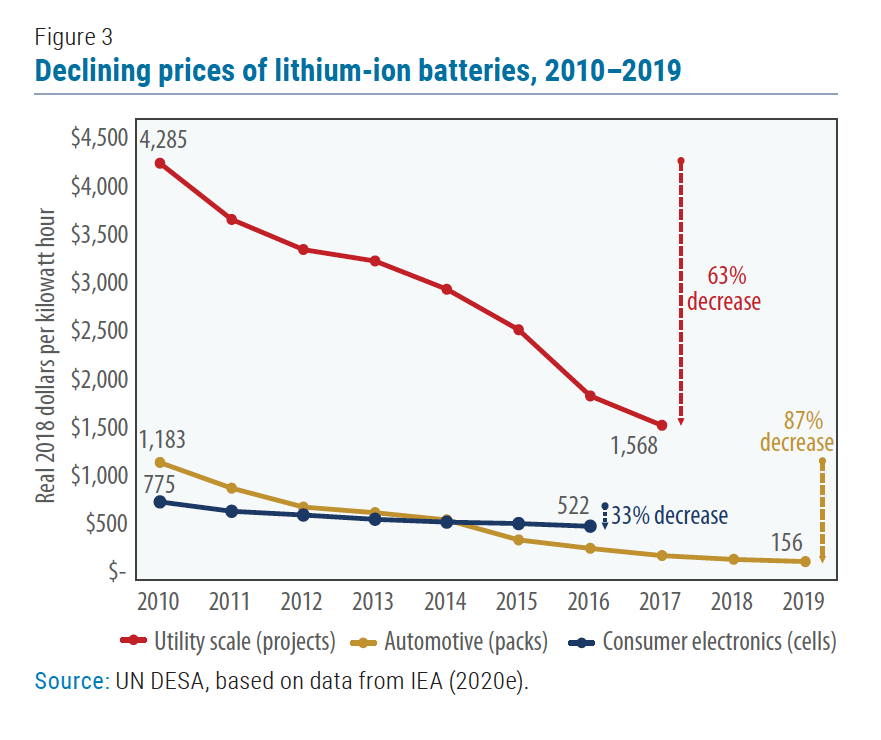

The increasing popularity of Li-ion batteries owes to its much-improved portability and significant price declines over a quarter-century since the introduction of the battery at the household level. At the beginning of the 1990s, the storage capacity that is required to power a regular-sized house in the United States for a day would have cost about $75,000 and the battery package would have weighed 111kg (equivalent to a size of a beer keg) (Economist, 2021). The same level of capacity can now be obtained at a cost of around $2,000 from a 40kg, small backpack-sized cell. Figure 3 shows a time series of Li-ion battery prices at 2018 constant US dollars per kilowatt hour (KWh). Since 2010, the cost per KWh of Li-ion batteries has dropped by 87 per cent.

Progress continues to accelerate. According to the International Energy Agency (IEA, 2020a), batteries in general account for nearly 90 per cent of all patenting activity in electricity storage, and that the rise in innovation has been largely driven by advances in rechargeable Li-ion batteries used in consumer electronic devices and electric cars. Solid-state Li-ion batteries are considered to be the next generation of Li-ion batteries for their higher energy density, safety and faster recharging times. At the same time, more affordable Li-ion batteries have been developed by replacing expensive cobalt—a critical substance—with more commonly available materials at the expense of energy density.

Progress continues to accelerate. According to the International Energy Agency (IEA, 2020a), batteries in general account for nearly 90 per cent of all patenting activity in electricity storage, and that the rise in innovation has been largely driven by advances in rechargeable Li-ion batteries used in consumer electronic devices and electric cars. Solid-state Li-ion batteries are considered to be the next generation of Li-ion batteries for their higher energy density, safety and faster recharging times. At the same time, more affordable Li-ion batteries have been developed by replacing expensive cobalt—a critical substance—with more commonly available materials at the expense of energy density.

The importance of batteries in the transportation sector

As the battery energy density has soared and prices have dropped, the Li-ion battery has become the major source for the electrification of various sizes of vehicles such as bicycles, scooters, cars, buses, trucks, and even ferries.4 Shipping and aviation are also making electrification progress, though at the very infant stage. Battery technology has the potential for further becoming a great enabler for sustainable transport.

Electrification of the transportation sector

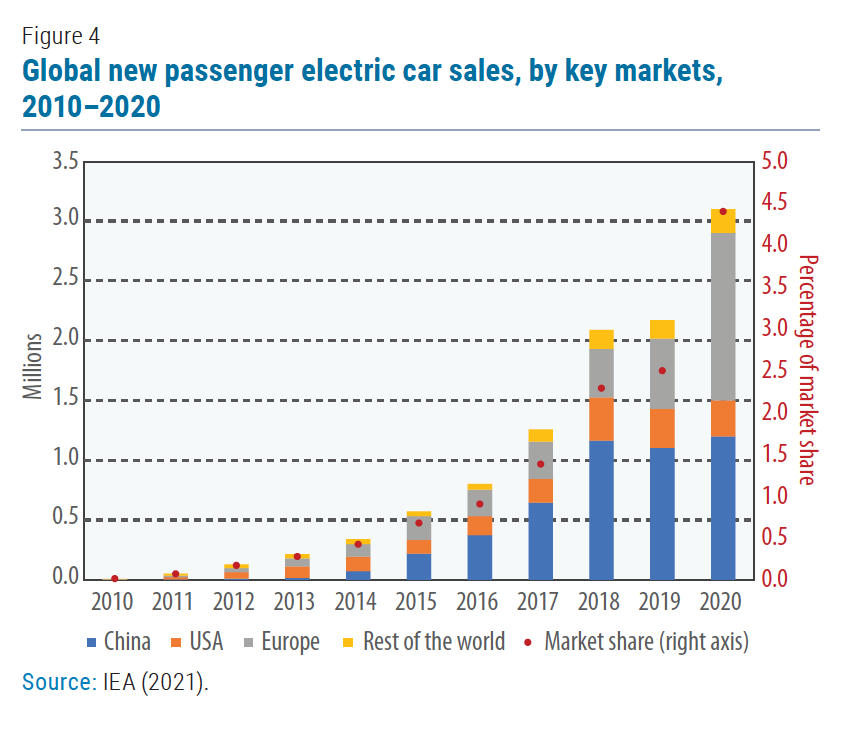

Sales of new passenger electric vehicles have significantly increased leading to the year 2019, when sales temporarily slowed down to 2.1 million globally (figure 4) (IEA, 2020c). Despite the COVID-19- pandemic, however, the combined effects of existing policies and targeted stimulus responses are estimated to have increased the global sales of new passenger electric vehicles by 40 per cent, reaching over 3 million in 2020, with a market share of new car sales of over 4 per cent (IEA, 2021). Some countries in Europe provided an additional boost to compensate for the impacts of the COVID-19 crisis and re-asserted their targeted support to electric vehicles as part of their economic stimulus programs. At the end of 2020, more than 10 million passenger electric vehicles are estimated to be on the road, making 2020 a record-breaking year for electric mobility.

Sales of new passenger electric vehicles have significantly increased leading to the year 2019, when sales temporarily slowed down to 2.1 million globally (figure 4) (IEA, 2020c). Despite the COVID-19- pandemic, however, the combined effects of existing policies and targeted stimulus responses are estimated to have increased the global sales of new passenger electric vehicles by 40 per cent, reaching over 3 million in 2020, with a market share of new car sales of over 4 per cent (IEA, 2021). Some countries in Europe provided an additional boost to compensate for the impacts of the COVID-19 crisis and re-asserted their targeted support to electric vehicles as part of their economic stimulus programs. At the end of 2020, more than 10 million passenger electric vehicles are estimated to be on the road, making 2020 a record-breaking year for electric mobility.

Electric vehicles have so far served the richer segment of global consumers—the ones who could afford to buy this relatively expensive mode of transformation and find electric vehicles an ideal choice for curbing climate change. The IEA predicts that the number of passenger electric vehicles on the road around the world could hit 125 million by 2030, but as high as 220 million could be on the road by 2030 if governments would undertake more aggressive policies and regulations to fight climate change and cut GHG emissions.

Larger vehicles are electrifying, as well. There are about half a million electric buses (E-buses) on the road, most of which are in China. The E-buses have been used as inner-city transport, and not for long distances, as their shorter ranges are more suitable for electrification. Similarly, the electrification of larger trucks is mostly in urban environments. Electrification of long-distance buses and heavy freight trucks have been dismissed as too costly, as the energy density of Li-ion batteries is too low to compete with the range that conventional buses and trucks cover with a single refueling. Global sales of electric trucks remained low but, as battery technology is improving rapidly, long-distance buses and heavy trucks are forecast to become more competitive (Nykvist and Olsson, 2021).

Electric vehicles and CO2 emissions

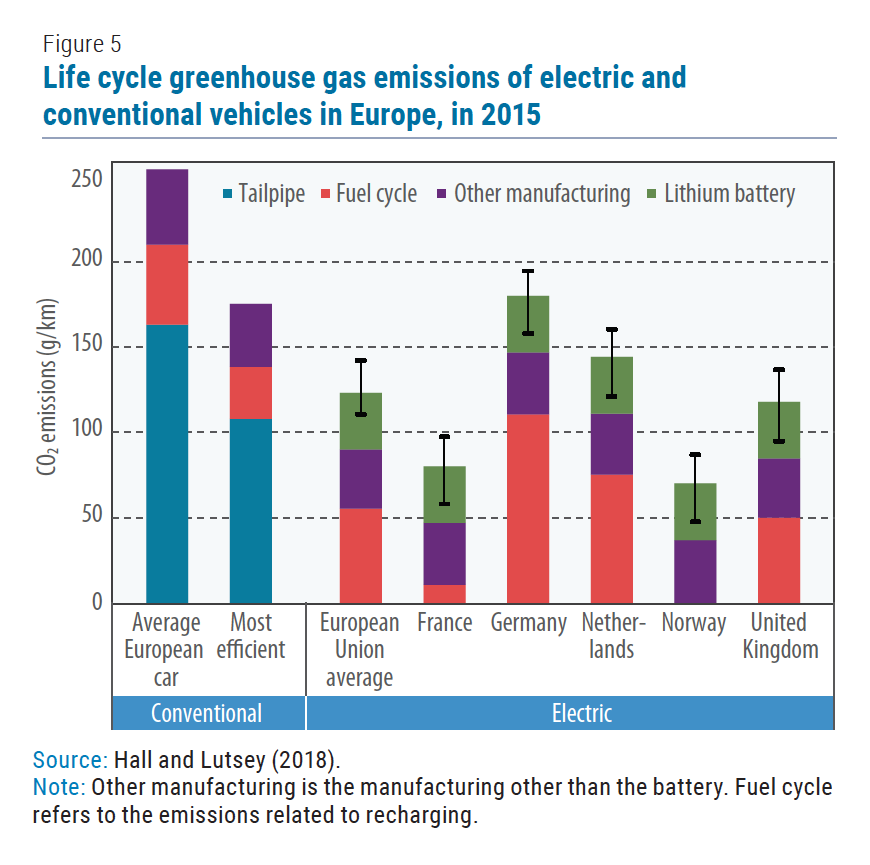

Currently, private vehicles—both electric vehicles and conventional cars—emit around 5 billion tons of CO2 annually, with a total annual CO2 emission at around 36 billion tons in 2018. Electric vehicles can reduce CO2 emissions in the transportation sector, with benefits including zero tailpipe emissions. But the electricity is still produced from fossil fuels in many countries, and there are emissions stemming from the manufacturing of the vehicle and the battery. The manufacturing of electric vehicles generally produces more emissions than a conventional car because of the batteries, but on average, electric vehicles account for fewer emissions through the fuel production and vehicle use phases. The life cycle emissions of electric vehicles depend on the CO2 intensity of power generation and in high-carbon intensity electricity systems, electric vehicles might save little CO2 compared to conventional vehicles. Maximizing the use of renewable energy to power electric vehicles is therefore particularly important for sustainable transportation.

Currently, private vehicles—both electric vehicles and conventional cars—emit around 5 billion tons of CO2 annually, with a total annual CO2 emission at around 36 billion tons in 2018. Electric vehicles can reduce CO2 emissions in the transportation sector, with benefits including zero tailpipe emissions. But the electricity is still produced from fossil fuels in many countries, and there are emissions stemming from the manufacturing of the vehicle and the battery. The manufacturing of electric vehicles generally produces more emissions than a conventional car because of the batteries, but on average, electric vehicles account for fewer emissions through the fuel production and vehicle use phases. The life cycle emissions of electric vehicles depend on the CO2 intensity of power generation and in high-carbon intensity electricity systems, electric vehicles might save little CO2 compared to conventional vehicles. Maximizing the use of renewable energy to power electric vehicles is therefore particularly important for sustainable transportation.

According to Hall and Lutsey (2018), overall, electric vehicles typically have lower life-cycle GHG emissions than a typical car in Europe, but the emissions reduction depends on the country and the carbon intensity of local electricity production. When comparing with the most efficient internal combustion engine vehicle, a typical electric car in Europe produces 29 per cent less GHG emissions throughout its life cycle (figure 5).

However, the overall impact of transport electrification on emissions is complicated and different studies take different approaches to quantify the impact. According to estimates from IEA (2020d), based on the current electricity mix, replacing a ten-year-old conventional vehicle with a battery-electric vehicle would generate lifetime emissions savings of 80 per cent in the European Union, 60 per cent lower in the United States and around 40 percent lower in China.

The United Nations Environment Programme (UNEP) has developed the electric mobility calculator to estimate the benefits of a large-scale deployment of electric vehicles. In the baseline scenario, it is expected that battery electric vehicles would reach a 5 per cent share of private vehicles by 2050 while, in an optimistic scenario, they would reach a 60 per cent share of total private vehicles in 2050. Comparing these two scenarios, in the optimistic scenario, more than 50 billion tons of CO2 could be prevented from being emitted into Earth’s atmosphere between now and 2050, when compared to the baseline scenario (figure 6).

The United Nations Environment Programme (UNEP) has developed the electric mobility calculator to estimate the benefits of a large-scale deployment of electric vehicles. In the baseline scenario, it is expected that battery electric vehicles would reach a 5 per cent share of private vehicles by 2050 while, in an optimistic scenario, they would reach a 60 per cent share of total private vehicles in 2050. Comparing these two scenarios, in the optimistic scenario, more than 50 billion tons of CO2 could be prevented from being emitted into Earth’s atmosphere between now and 2050, when compared to the baseline scenario (figure 6).

The importance of batteries for the energy sector

As examined in UN DESA (2020), energy storage can help bring modern energy for all, particularly in the sub-Saharan region, where the share of the population with access to modern energy is low. The use of stationary energy storage must grow faster in the coming decades if we are to meet the climate change and sustainable energy Goals. Utility-scale stationary energy storage is in high demand thanks to the growing share of renewable sources of energy—solar and wind—whose power generating capacities vary depending on sun coverage and wind speeds. The large declines in the cost of Li-ion batteries also make it the favored battery technology for stationary storage projects.

Lithium-ion batteries as storage for electrical utilities

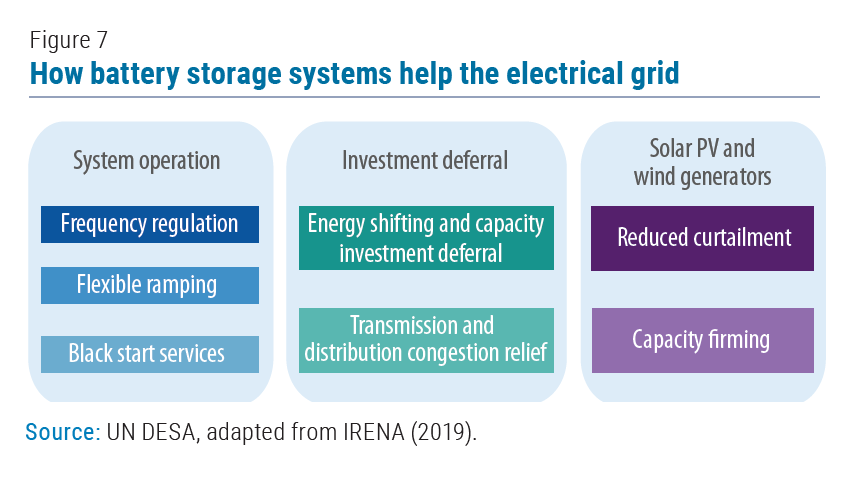

Battery storage helps renewable generators reliably integrate with existing grids by storing the excess generation and by smoothing the energy distribution. Batteries can store surplus solar and wind power and distribute it when needed. As more installations are built, electrical grids can accommodate a growing share of variable renewal energy generators such as solar and wind power plants. Batteries also help traditional suppliers manage the stability of energy distribution thanks to their unique ability to quickly absorb, store, and deliver electricity as needed. Among its many uses, batteries help operators regulate the frequency of the electrical current—an important aspect of electricity transmission— help store electricity until transmission capacity is available, and help maintain capacity reserves. Batteries also make isolated and off-grid installations viable and less dependent on diesel generators (figure 7).

Battery storage helps renewable generators reliably integrate with existing grids by storing the excess generation and by smoothing the energy distribution. Batteries can store surplus solar and wind power and distribute it when needed. As more installations are built, electrical grids can accommodate a growing share of variable renewal energy generators such as solar and wind power plants. Batteries also help traditional suppliers manage the stability of energy distribution thanks to their unique ability to quickly absorb, store, and deliver electricity as needed. Among its many uses, batteries help operators regulate the frequency of the electrical current—an important aspect of electricity transmission— help store electricity until transmission capacity is available, and help maintain capacity reserves. Batteries also make isolated and off-grid installations viable and less dependent on diesel generators (figure 7).

While there are many technologies used for utility-scale energy storage, rechargeable Li-ion batteries have become favored in new installations due to their flexibility and scalability, and their declining costs.6 Cost improvements continue as electric vehicle manufacturers invest heavily in improving the design and manufacturing of rechargeable batteries. The low and declining cost of Li-ion batteries has made the technology the preferred choice for new utility-scale battery storage additions (IEA, 2020f). In the United States, average project costs decreased from $2,152 per KWh of installed storage in 2015 to $625 in 2018 (U.S. Energy Information Administration, 2020). As a result, Li-ion batteries account for over half of all new stationary battery installations since 2013, and nearly 90 per cent in 2016 (figure 8). In recent years, a number of large-scale installations have been completed. In 2017, Tesla installed the (then) world’s largest Li-ion battery system at the Hornsdale Wind Farm in South Australia to help the region solve its recurring power outages. In 2020, the capacity was expanded by 50 per cent owing to its success. Also, in 2020, the world’s largest Li-ion battery was installed in California.

Batteries enable a faster transition to renewable energy

Batteries enable a faster transition to renewable energy

Energy storage plays a key role in the transition to renewable sources of electricity, though the importance depends on the appropriate mix of renewable and clean energy sources (Ratz et al., 2020). As the combined cost of renewable energy generation and battery storage becomes competitive with conventional energy sources, electrical utilities will be able to replace larger portions of current electricity sources with carbon-free alternatives. This is an important point as replacing traditional vehicles with electric vehicles for environmental sustainability also requires a clean source of electricity with which to charge the batteries.

Studies show that carbon emission reductions of 50–80 per cent are possible using mostly solar and wind sources (coupled with storage) and with smaller contributions from other low-carbon sources (nuclear, bioenergy, and carbon-capture natural gas plants). Greater reductions are possible using a higher proportion of non-variable clean sources (nuclear, hydro plants, coal and natural gas with carbon capture and storage, geothermal, and bioenergy) (ibid.).

In all scenarios, significant energy storage and transmission investments are required to provide grid stability, reliability, and economic feasibility. For instance, by reducing the revenue losses from curtailment—when renewable generation exceeds the demand from the grid—storage can make renewable energy investments more profitable and more likely to displace coal and gas generators. For small grids in remote locations, battery storage makes solar and wind installations a more attractive option. In a local community in Hawaii, a 1 megawatt/hour battery system connected to an off-grid solar plant is expected to reduce their use of fossil fuels by 97 per cent. In Martinique, energy storage connected to a solar plant will remove the need of additional back-up generators using fossil-fuels (IRENA, 2019).

There is some hope for decoupling between electricity generation and emissions as renewable energy sources come online. The demand from non-renewable sources dropped by more than 3 per cent in 2020. Electricity generated from coal sources dropped by 4.4 per cent globally, and by 20 per cent in the United States. At the same time, solar and wind generation grew in 2020 by 12 and 23 per cent, respectively, following a nearly 20-year period of positive growth. The IEA expects that over half of the additional global electricity supply in 2021 will come from renewable sources. For small installations in remote locations and islands, installing battery-systems to accompany renewable energy generation is relatively easy and cost-effective. It also reduces the need for high-pollution diesel generators.

Policies towards a fossil fuel-free economy

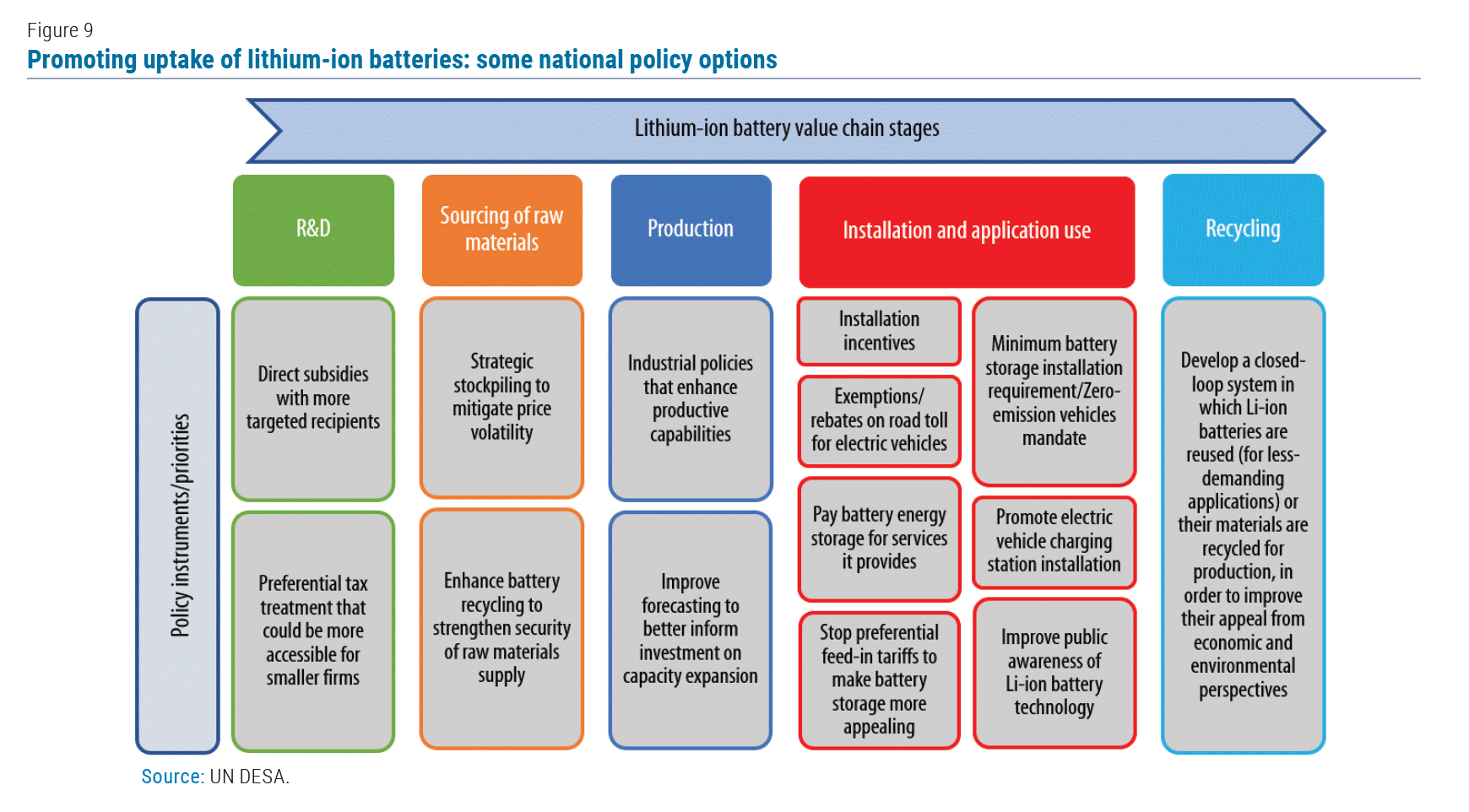

Electric vehicles and storage systems have become more competitive alternatives to conventional vehicles and stationary energy installations. But there are still technical, economic and environmental challenges that the global community as a whole has to address in order to build a fossil fuel-free economy. This last section considers the role of governments in promoting the uptake of Li-ion batteries to build a fossil fuel-free economy (see figure 9).

Research and development

Further decline in prices of Li-ion battery and its improved capacity would partly depend on continued R&D efforts. Fiscal support can catalyze such efforts by improving their financial returns, but governments must also account for the significant uncertainty of the cost of such support. A review of policies in countries playing major roles in Li-ion battery development shows that direct subsidies are generally favoured over tax instruments as a form of fiscal support.7 It could partly reflect the fact that subsidies give governments more control in terms of the recipients of the support as well as the direction of innovation. The nature of direct subsidies is therefore more discretionary, and its effectiveness relies on how well governments can target, based on relevant information on the size and reach of direct and spillover effects of selected R&D activities.

In the case of Japan, there is a long history of direct government funding support for R&D in lithium-based batteries. Research on lithium-based batteries has been carried out under the country’s government-supported programme such as the New Sunshine Program since 1992 (APEC, 2017). These government-funded programmes typically take a long-term perspective (4–10 years). Firms are expected to shoulder more financial responsibility as the technology becomes more mature; firms conducting battery research could get 100 per cent government funding at the early stage of the programme but receive between 50 to 67 per cent as the technology approaches commercialization.

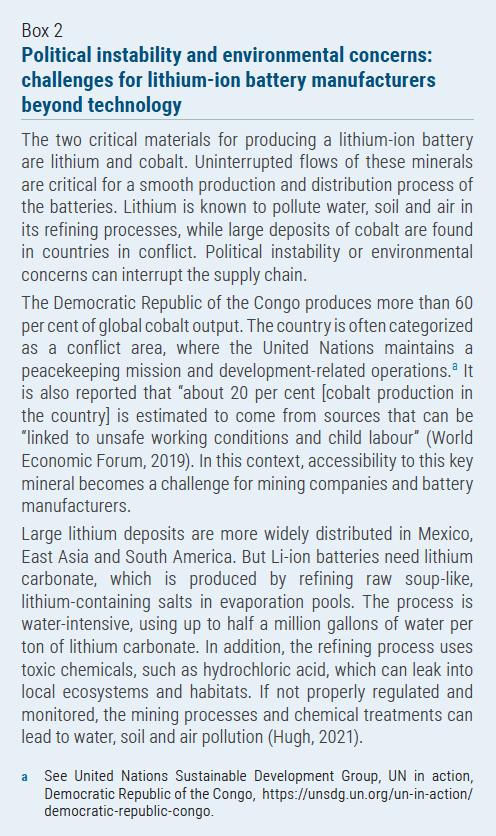

Sourcing of raw materials

A key cost component of the Li-ion battery production is the price of its raw materials, including lithium, cobalt, graphite and manganese. Maintaining the price stability of these materials would involve close monitoring of their production and price cycles and employing appropriate strategies to mitigate price volatility and prevent supply shortfalls. These could include strategic stockpiling of raw materials. McKinsey reported that countries have been engaging in strategic stockpiling of cobalt. For example, between 2015–2017, it is reported that China’s State Reserve Bureau purchased cobalt for its stockpile, which was estimated to be around 5 kilotons per year (Azevedo et al., 2018). Expanding efforts to recycle raw materials could also help to address concerns over supply security and price stability.

Policymakers should be aware that key materials, such as lithium and cobalt, are produced only in a few countries and, in some instances, their supplies could hardly catch up with rapidly increasing demand (see box 2). Producing countries have often restricted exports of the materials for political gains. There have also been concerns about social and environmental impacts of mining the mineral in the country. Similar concerns have also been raised in several lithium-producing countries.

Production

The battery pack is the single most expensive part of an electric vehicle, accounting for about 30 per cent of the total cost to consumers. In the auto industry, it is generally accepted that $100 per kWh for battery packs is the price point needed for electric vehicles to be cost-competitive with gasoline-powered vehicles. But, as seen in figure 3, the cost dropped only to $156 per kWh in 2019. The cost of producing Li-ion batteries can be further reduced through economies of scale. Certain industrial policies can help to expand domestic productive capabilities, which could include incentive-linked performance requirements, targeted investment promotion in manufacturing facilities, and supplier development programmes. Improving forecasting to better inform investment on capacity expansion would also be important.

The battery pack is the single most expensive part of an electric vehicle, accounting for about 30 per cent of the total cost to consumers. In the auto industry, it is generally accepted that $100 per kWh for battery packs is the price point needed for electric vehicles to be cost-competitive with gasoline-powered vehicles. But, as seen in figure 3, the cost dropped only to $156 per kWh in 2019. The cost of producing Li-ion batteries can be further reduced through economies of scale. Certain industrial policies can help to expand domestic productive capabilities, which could include incentive-linked performance requirements, targeted investment promotion in manufacturing facilities, and supplier development programmes. Improving forecasting to better inform investment on capacity expansion would also be important.

To encourage firms to build production capacities for advanced batteries, India announced in 2020 a multi-billion-dollar production-linked incentive scheme that will begin with cash and infrastructure incentives (Singh, 2020). It is reported that, under this type of scheme, firms can expect to be paid an amount equivalent to 4–6 per cent of their incremental sales, in addition to the base-year level. This scheme will go hand in hand with the country’s existing import tax on certain batteries that protect the nascent domestic battery industries (Arora and Ahmed, 2020). To ensure long-term competitiveness of these industries, protectionist measures must be employed with caution and only for a finite period of time, while complying with international trade regulations.

Installation and application use

Promoting installation and use of Li-ion batteries is an area where both market-based and non-market-based instruments are commonly employed.

Market-based instruments

In terms of market-based instruments, governments can improve overall economic returns to the installation of Li-ion batteries by introducing monetary rewards at different points. First, direct subsidy or preferential tax treatment can be given when Li-ion batteries are installed. For example, the German government and its development bank, KfW, provide low-interest loans and repayment bonuses for batteries in conjunction with photovoltaic systems (Potau et al., 2018). Levy and grid tariff exemptions are also given to grid-connected electricity storage facilities. For electric vehicles, countries introduced measures such as exemptions or rebates on road toll to accelerate their adoption.

Second, efforts can be directed at creating possibilities for monetizing value streams/services that Li-ion batteries can provide once installed. For example, it is often found that deregulated power markets and regulated utility operators do not pay battery energy storage—either by households or businesses—for its support to mitigating power fluctuations to the grids and maintaining their overall stability (Stenclik et al., 2018). In other words, regulatory authorities do not usually recognize the dual role that electricity storage system plays in the grid systems. The battery is a buyer of electricity from the grid when it is charging, but a seller when discharges. The seller contributes to congestion relief, renewable integration, and arbitrage, etc., and it is important for regulators to recognize the role that energy storage providers play in building the fossil fuel-free economy.

Third, another approach to incentivize the installation of Li-ion batteries is to reduce the attractiveness of the alternatives. For example, some European Union countries stopped the payment of preferential tariffs for feeding electricity from renewable energy sources into the grid, which makes using battery storage more appealing in comparison (Potau et al., 2018).

Non-market-based instruments

Non-market-based instruments that involve imposing obligations or introducing non-monetary incentives also play a role in supporting Li-ion battery installation.

In some areas such as electric vehicles, there has been a recent shift from market-based instruments such as direct subsidies to non-market-based instruments. Authorities in some countries have introduced zero-emission vehicle mandates and fuel economy standards. Others established low-emission zones, where only electric or hybrid cars are allowed.

For electric utilities, governments could require utility or grid operators to install a minimum capacity of battery storage. Such requirements can help to develop pilot projects and promote industry learning (Stenclik et al., 2018). Policymakers can also invest in improving public understanding of battery storage and its related benefits. This could help attract those that have shied away from decentralized solutions such as battery storage due to concerns over reliability, economic viability, safety, and data security, among others.

Another non-market-based instrument is to promote the installation of charging stations, as there is a strong correlation between the availability of charging infrastructure and electric vehicle uptake. Countries have been building charging infrastructure along road and fuel stations and introduced provisions in building codes to encourage charging facilities. However, the expansion of the charging infrastructure remains a key challenge for the widespread adoption of electric vehicles.

One of the obstacles to the installation of charging stations is the so-called land squeeze for personal electric vehicles. In many urban areas, there is a lack of ability to establish private charging at home and parking garages are rarely equipped with charging outlets. Only 40 per cent of European and 30 per cent of Chinese electric vehicle owners have access to private parking with wall charging, versus 75 per cent of US electric vehicle owners. For the adoption of electric buses and trucks that need fast, high-capacity charging, the challenge is even greater, and it creates large pressure on improving the grid in local areas. An alternative approach to grid improvement could be the use of stationary energy storage using Li-ion batteries for key charging stations.

In most countries, the power facilities can accommodate a significant rise in the number of electric vehicles, if the vehicles are charged in off-peak periods. However, if a large share of vehicles is charged at peak times and/or by fast chargers, improvement of the power facilities will be required. It will be important for all countries to consider the electrical grid capacity well in advance to identify any limitations before the adoption of electric vehicles increase further. The countries need to accumulate various experiences with storage installations—including how to price and manage the business operations of battery installations—before projects can be scaled-up. It is important that countries establish pilot projects and knowledge exchanges that help operators and regulators better understand the technology, especially for smaller countries where there are fewer installation opportunities.

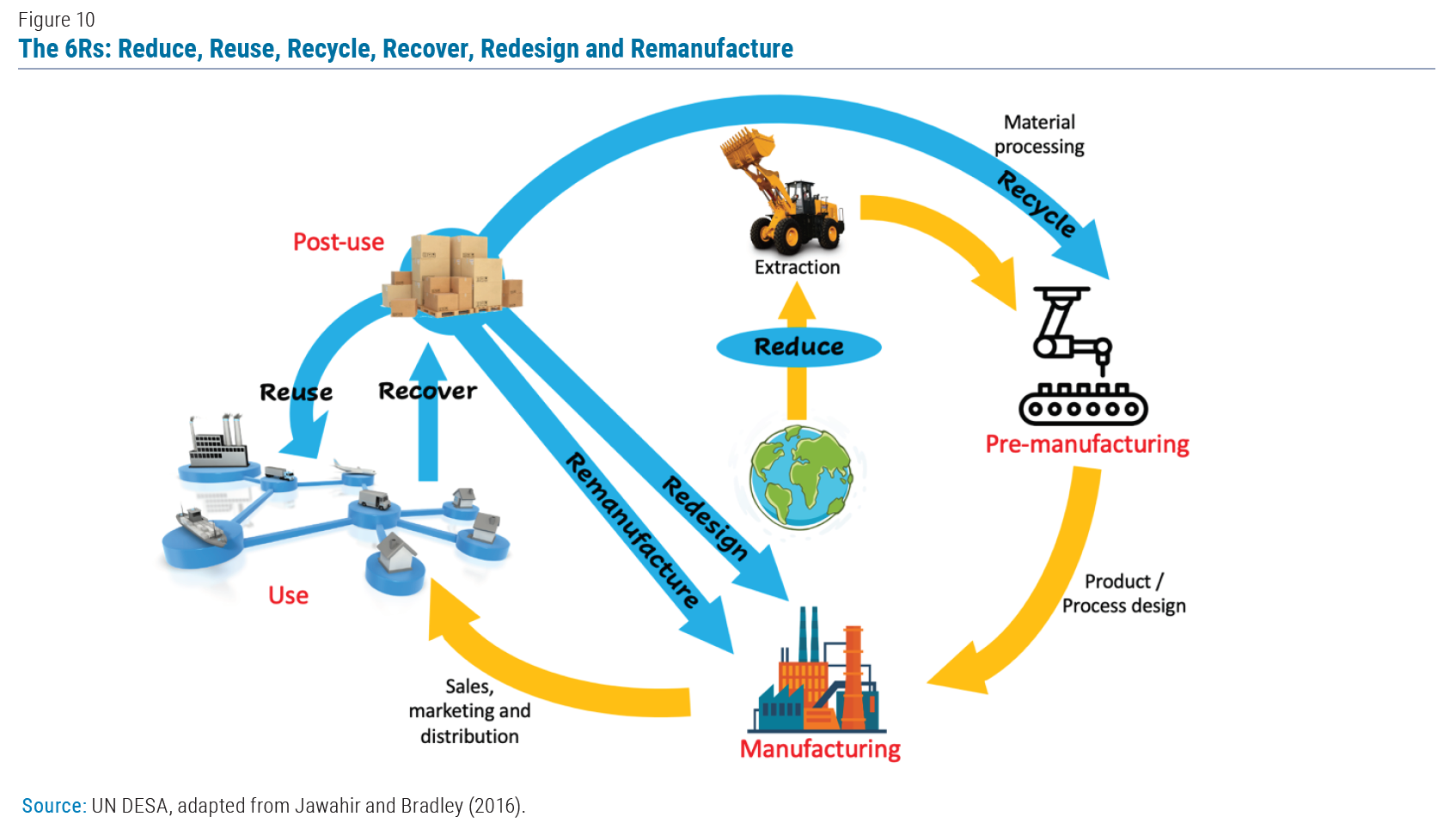

Recycling and closing the material loop

Li-ion batteries are not toxic in the same way as nickel cadmium or lead-acid batteries, but they do contain chemicals that should not be exposed to the environment. Establishing a cycle of reuse, recycling and waste management can be a significant and positive contribution from both an economic and an environmental perspective.

Li-ion batteries that are no longer useful in their first application can still be used in other less demanding applications. For example, batteries used in electric vehicles become unusable after about 100,000 miles of driving, but can be re-used as back-up power to energy storage systems or telecom systems.

If not reused, the precious metals in Li-ion batteries, such as cobalt, lithium, copper and iron, can be recycled. The US has developed a successful system of recycling lead batteries with a 99 per cent recycling rate for 2014–2018, the highest among consumer products (Smith Bucklin Statistics Group, 2019). Unfortunately, Li-ion batteries are not compatible with the lead battery recycling process. At present, a nationwide independent system of recycling Li-ion batteries is not in place as it is more expensive to recycle than to produce these batteries from scratch. Only about 5 per cent of Li-ion batteries are estimated to have been recycled (Miller, 2020) and the declining prices of Li-ion batteries have made recycling relatively more costly.

Several enterprises in China, Europe and North America have started innovative recycling projects to extract metals from Li-ion batteries (Economist, 2021b). Some of them attempt to create “closed-loop” systems, in which metals are recovered from the batteries that are produced by their own factories. The European Investment Bank has recently offered a loan of about $350 million to a Swedish battery developer and manufacturer—in addition to finances from major European automobile makers—to supply Li-ion batteries to the European makers as well as to establish the closed-loop system (European Investment Bank, 2020).

These closed-loop systems need to be expanded so that no matter who manufactures the Li-ion batteries, or where, the metals used are recovered and reused. To realize such a loop, battery manufacturers are required to design recyclable batteries from the beginning. The solid-state Li-ion battery, mentioned previously, is thought to be more easily dismantled than the current types of batteries, thus producing less e-waste and yielding greater levels of purity of each metal at the time of extraction. A closed-loop material flow system expands on the idea of “reduce, reuse, recycle” and aims to make battery manufacturing sustainable. Closing the loop also requires recovering batteries from ending in landfills, redesigning batteries to be more environmentally friendly, and remanufacturing batteries to give them new life (see figure 10).

Lithium-ion batteries have indeed become the critical pillar for building a fossil fuel-free economy. The batteries can safely store energy for mobile and stationary use and ensure stable and uninterrupted flows of energy even when solar or wind power is used. But, to maximize their contributions, energy should be produced in a fossil-free manner. Governments and the international community are required to help advance more powerful and affordable Li-ion batteries, promote their use and create the closed-loop recycling system.

Follow Us