When it comes to refrigerant leak detection, the predominant sensing technologies are undoubtedly Non-Dispersive InfraRed (NDIR) and Metal-Oxide Semiconductor (MOS). NDIR is the most performing technology, but its cost has so far prevented a widespread use in light commercial and residential applications, where MOS has remained the predominant choice.

Although MOS requires periodic calibration (normally every 6 months or less) and substitution every 2 to 4 years, other than suffering from interference from many chemicals other than the target gas and from dependency from environmental conditions, the affordable price has tipped the balance in its favor in settings like food retails, hotel rooms, apartments and offices.

This can now change with the IREF LITE series from N.E.T. – a complete line of NDIR sensors for refrigerant gas leak detection with a very cost-effective price. This will make the gas selectivity, accuracy, poison immunity and extended lifetime of NDIR technology affordable for any setting, dramatically improving gas detection performances in the HVAC-R market, improving occupants’ safety and lowering cost-of-ownership.

The IREF Lite series from N.E.T. include solutions for most A2L refrigerant gases both in ppm and %LFL range.

Aside the analogue output, IREF LITE provides also a user-programmable threshold output consisting of different voltage levels – by default, 10% LEL=1V, 25% LEL=1.5V. The user can freely select the output level, the corresponding output and the hysteresis of the thresholds through Modbus RTU commands.

In fact, digital communication via Modbus RTU commands allows complete access to the sensor functioning parameters, diagnostics and periodic recalibration.

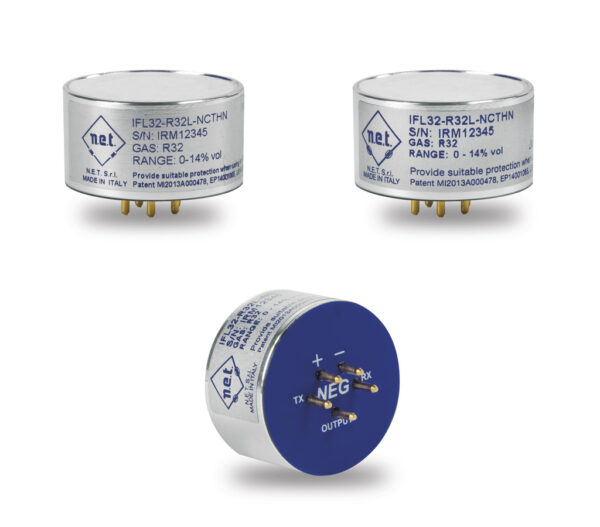

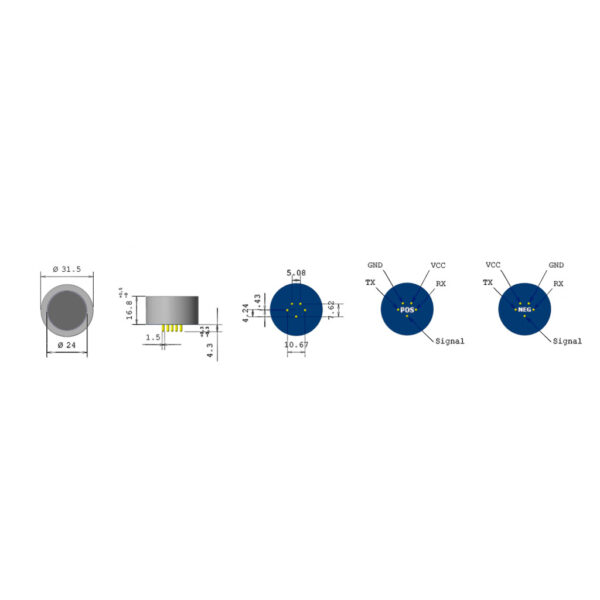

The standard industrial 7-series size and pinout fit existing detectors and is significantly smaller than most NDIR-based alternatives available.

In order to guarantee maximum safety, IREF LITE has been developed in order to meet SIL2 requirements (SIL is a quantitively measurement of the ability of a system to carry out its safety function when called to do so).

| MEASUREMENT RANGE | |

|---|---|

| ppm range: | LFL% range: |

| R-1234yf (0-5.000ppm) | R-1234yf (0-6.2%vol) |

| R-1234ze (0-5000ppm) | R-1234ze (0-6.5%vol) |

| R-134a (0-5.000ppm) | R-32 (0-14.4%vol) |

| R-32 (0-10.000ppm) | R-454a (0-6.3%vol) |

| R-404a (0-5.000ppm) | R-454b (0-7.7%vol) |

| R-407c (0-5.000ppm) | R-454c (0-6.2%vol) |

| R-410a (0-10.000ppm) | R-455a (0-11.8%vol) |

| R-449a (0-5.000ppm) |

- Download Center