Testing of in-service lubricants for their remaining antioxidant content is critical for prolonging the uptime of capital equipment as well as reducing running costs and repair expenses. Nevertheless, it is often not part of oil monitoring programs because the analysis is too time-consuming and expensive to perform. Voltammetry is a fast and established method for testing the remaining antioxidant content in industrial lubricants. By using a modern voltammetric measuring technique and an advanced evaluation algorithm, analysts can test samples more efficiently, improve the repeatability of results, and cut analysis costs.

The following topics will be covered in this article (click below to go to each directly):

- Why do lubricants contain antioxidants?

- Why does the remaining antioxidant content need to be determined?

- How are antioxidants determined by voltammetry?

- How repeatable is the determination of antioxidants with DPV?

- How reproducible is the determination of antioxidants with DPV?

- Which instruments can I use for the determination of antioxidants in lubricants?

- Where do I get the electrolyte for this application?

- Summary

Why do lubricants contain antioxidants?

Different base oils are used as lubricants depending on their area of application. Additives are used to enhance or suppress the base oil properties or to even create new properties.

One group of oil additives are antioxidants. Antioxidants extend the useful life of a lubricant by preventing the oxidation of the base oil.

Why does the remaining antioxidant content need to be determined?

Amongst other parameters, the remaining antioxidant content of in-service oils is determined to assess the status of the lubricant. This serves to identify the best possible time for lubricant replacement.

On one hand, the oil should be used as long as possible to save costs and reduce unnecessary waste. On the other hand, the oil has to be replaced before poor lubrication causes any damage to capital equipment.

How are antioxidants determined by voltammetry?

The principle of the method is that the aromatic amines and hindered phenols (which are used as primary antioxidants) in the lubricant sample are extracted into an electrolyte. They are then measured directly in this extraction solution. Voltammetric determination is possible because hindered phenols as well as aromatic amines contain a functional group that can be electrochemically oxidized. These functional groups (i.e., the amine and the phenol group) are marked red in the primary antioxidants shown in Figure 1.

For quantification, the signal obtained for an in-service oil is compared to the signal of the fresh oil, stating the result as % remaining antioxidant. Since the absolute concentration of additives in the fresh oil is usually unknown, the result obtained for the in-service oil is a relative value showing the change with respect to the fresh oil.

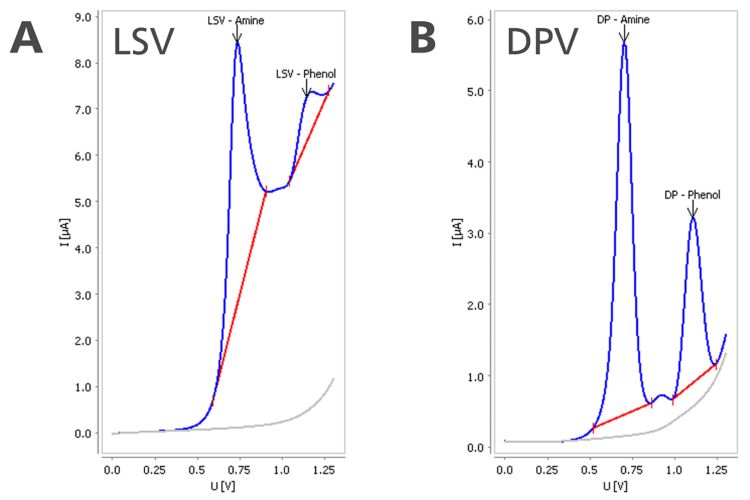

For the voltammetric measurement of antioxidants, two techniques can be used: linear sweep voltammetry (LSV) and differential pulse voltammetry (DPV). The classical LSV technique is described in the following standards: ASTM D6810 [1], ASTM D6971 [2], and ASTM D7590 [3]. Using DPV instead of LSV improves the shape of the peaks obtained for the oxidation of aromatic amines and hindered phenol. Figure 2 shows the curves measured using both LSV and DPV for comparison.

The advantages of DPV for routine analysis are obvious. The peaks are sharper, the peak resolution is improved, and the peaks are better separated from the background. Furthermore, a sophisticated evaluation algorithm ensures that peaks are evaluated automatically without further adjustments by the operator.

As a result, the peak evaluation is more reliable and more sensitive, and thus the repeatability and reproducibility of results improve.

How repeatable is the determination of antioxidants with DPV?

To verify the performance of a method, a check standard can be determined. A check standard is a sample with known content. In the case of lubricants, for which the absolute content of antioxidants is unknown, the same fresh oil sample is used for the calibration and as a check standard. The result should therefore be 100%.

Figure 3 shows the determination of remaining antioxidant content in check standards from different oil brands and types. Each data point represents the mean of duplicate or triplicate determinations with the corresponding error bar.

For easier assessment of the results, the repeatability limit according to ASTM D6971 for a content of 100% is also displayed in the graph (green lines). Results between 86.7% and 113.3% would still be within this limit. Most of the displayed results lie between 96% and 104%.

How reproducible is the determination of antioxidants with DPV?

Repeatability reflects the statistics of results obtained under identical conditions – meaning the same laboratory, equipment, and operator. However, reproducibility is a statistical measure comparing results obtained under differing conditions. For this purpose, the same sample is analyzed in different laboratories with different equipment and using different operators.

Figure 4 shows the results for the determination of aromatic amine content in the same turbine oil sample in eight different labs. Two of the labs used a manual system for lubricant analysis, whereas the other six carried out the determination on a fully automated system. For the assessment of these results, the reproducibility limits according to ASTM D6971 are also displayed in the graph.

The average aromatic amine (antioxidant) content found in this sample is 68.8%. According to ASTM D6971, the reproducibility limit would be 22.6% for a sample with this concentration. The reproducibility standard deviation found in this comparison was much better at just 2.8%.

Which instruments can I use for the determination of antioxidants in lubricants?

The voltammetric system Metrohm provides for the determination of remaining antioxidants in lubricants is the 884 Professional VA. This is a highly flexible, modular voltammetry system designed for routine analysis in the lab.

The manually operated system consists of the 884 Professional VA which is controlled by the viva software that runs on a Windows PC. Furthermore, viva takes care of the curve evaluation and result calculation. By extending the manual 884 Professional VA with a sample changer, dosing devices, and peristaltic pumps, the complete analysis procedure including the sample preparation can be automated. The only manual step required in this case is to place the sample on the rack of the sample changer. Figure 5 shows this fully automated setup on a laboratory bench.

Although the total analysis time per sample is not any shorter when using an automated system, automation allows nearly 80% of the analysis time to be saved during which the operator can attend to other important tasks in the lab. Furthermore, an automated system also allows samples to be run outside of the usual working hours, meaning the analytical instrument can be used more efficiently and sample throughput can be increased.

Where do I get the electrolyte for this application?

The use of the 884 Professional VA does not require any proprietary test solutions. Compared to commercially available test solutions, the necessary electrolytes can be prepared in the lab for a fraction of the cost.

Summary

The Metrohm voltammetry setup discussed in this article improves the determination of primary antioxidants in lubricants in several ways—one of which is relegating time-consuming manual peak interpretation to a thing of the past.

Most importantly, the VA instrument delivers repeatable and reproducible results which exceed ASTM requirements. Additionally, the system allows costs to be cut because it does not require the use of expensive commercial test solutions. Finally, if the number of samples requires it, the 884 Professional VA can be extended to a fully automatic system at any time.

References

[1] ASTM International - Subcommittee D02.09.0C. ASTM D6810-21 - Standard Test Method for Measurement of Hindered Phenolic Antioxidant Content in Non-Zinc Turbine Oils by Linear Sweep Voltammetry. https://doi.org/10.1520/D6810-21 (accessed 2021-08-13).

[2] ASTM International - Subcommittee D02.09.0C. ASTM D6971-09(2014) - Standard Test Method for Measurement of Hindered Phenolic and Aromatic Amine Antioxidant Content in Non-zinc Turbine Oils by Linear Sweep Voltammetry. https://doi.org/10.1520/D6971-09R14 (accessed 2019-03-01).

[3] ASTM International - Subcommittee D02.09.0C. ASTM D7590-09(2014) - Standard Guide for Measurement of Remaining Primary Antioxidant Content In In-Service Industrial Lubricating Oils by Linear Sweep Voltammetry. https://doi.org/10.1520/D7590-09R14 (accessed 2021-03-06).

Your knowledge take-aways

Application Note: Remaining Useful Life of lubricants

Brochure: 884 Professional VA – Universal system solution for voltammetry and CVS

Share via email

Share via email